Midplane Cavity Housings: VH 6030

We can optimize this portable and customizable cavity/housing design to your specific application needs.

Our understanding of the finite element modeling of temperature effects on a wide variety of cavity/housing combinations, and our skill in their build, allows us to capitalize on the flexibility inherent in the vertical mounting of midplane cavities. From dual stage temperature stabilization to fiber coupled, transportable, and hermetically sealed vacuum housings, we can create the exact solution you require in a fraction of the time you would need to design it.

Get the customization you need in a portable cavity/housing

Performance & Specs

| Frequency Drift | < 15 kHz/day at zero crossing temperature, 1550 nm |

| Temperature Drift | < 7 mK/°C |

| Temperature Control Range | 25 – 45°C |

| Thermal Time Constant | 4 hours |

| Achievable Pressure | < 10-6 Torr |

| Vacuum can | Aluminum, with mounting forks for 1″ posts |

| Viewports | AR coated windows angled at 2° with respect to can axis |

| Fittings | Stainless steel tee with two Conflat fittings for ion pump & valve |

| Temperature Control | 6 Ω heaters as standard |

| Thermistors | Two: 10 kΩ @ 25°C |

| Weight | 6 kg |

Download Full Specs

Features

- < 7 mK/°C temperature drift over a modest operating temperature range

- Mounting structure optimized for rigidity and low thermal expansion

- Optional mode matching from fiber to cavity

- Can be optimized for commercially available or custom cavity designs

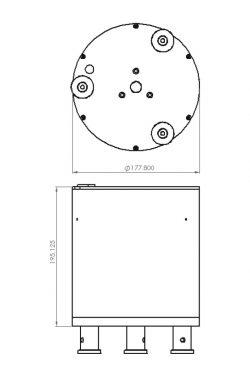

Engineering Diagram

Customization Options

- Each cavity housing is built to order and fully customized to the application

- Fiber coupling, with mode matching from fiber to cavity of ~90%

- Dual stage temperature stabilization/isolation

- Transportable housings without loss of alignment