Cylindrical and Notched Cavity Housings: VH 6010/6020

Cylindrical and notched cavities are a favored solution for Hz-level spectroscopy, and we understand them best.

We use carefully modeled mounting supports thoroughly tested to minimize acceleration sensitivity, in a vacuum housing designed for rigidity, low thermal expansion, and vibration damping. Our cavity/housing pairs offer notably low drift over a wide range of temperatures. We recommend notched cavities rather than cylindrical cavities at linewidths below 100 Hz for best acceleration sensitivity and performance.

Tried and true convenience & performance, delivered

Performance & Specs

| Frequency Drift | < 5 kHz/day at zero crossing temperature, 1550 nm |

| Temperature Drift | < 7 mK/°C |

| Temperature Control Range | ambient to 40°C |

| Thermal Time Constant | 4 hours |

| Achievable Pressure | < 10-6 Torr |

| Vacuum can | Aluminum, with mounting forks for 1″ posts |

| Viewports | AR coated windows angled at 2° with respect to can axis |

| Fittings | Stainless steel tee with two Conflat fittings for ion pump & valve |

| Temperature Control | 6 Ω heaters as standard |

| Thermistors | Two: 10 kΩ @ 25°C |

| Weight | 8 kg |

Features

- < 7 mK/°C temperature drift over an intermediate operating temperature range (25 – 45°C)

- Notched cavity options with even lower acceleration sensitivity for linewidths below 50 Hz

- Optional mode matching from fiber to cavity

- Can be optimized for commercially available or custom cavity designs

- Adapts well to transportable and dual stage designs

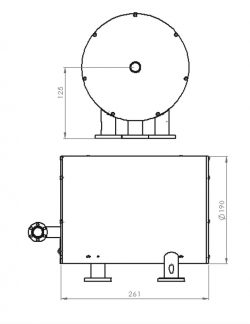

Engineering Diagram

Customization Options

- Each cavity housing is built to order and fully customized to the application

- Fiber coupling, with mode matching from fiber to cavity of ~90%

- Dual stage temperature stabilization/isolation

- Transportable housings with rotary clamp feedthrough

- Radiation shield option available to give thermal time constant of 7 hours